Apart from Honda, Yamaha and Aprilia, another manufacturer which was actually quite serious and massive in testing new aerobodies in the Jerez test last Monday was the KTM manufacturer. Several photos from Michelin and GPOne during the 2024 Jerez test are enough to show KTM’s seriousness in trying to get rid of Ducati’s influence on their motorbike this time.

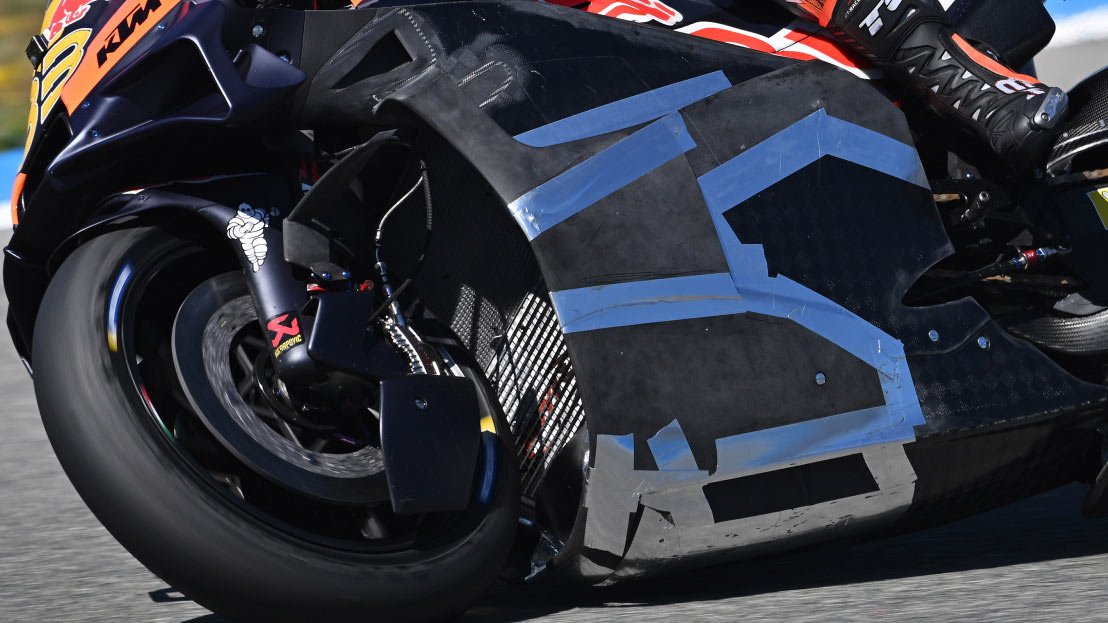

One thing that makes we confident in efforts to eliminate Ducati’s traces of this is the disappearance of the diffusser down-wash duct which was present in the initial version of the 2024 aerobody solution (check Dani Pedrosa’s photo above) and was even openly copied by HRC for the lab motorbike version or what we says is the 2024 RC213V Jerez version. Yes, in the design solution in the Jerez test, the downwash duct is completely gone!!

What made we quite surprising was that KTM was seen making two new side fairing solutions. The first is to simply replace the downwash duct model with a convex bulge detail from the lower front fairing. This leaves a slightly hollow area in the middle between the bulging detail and the sidepod.

You can see the second solution in the picture above where the convex bulging fairing at the bottom is designed as a ‘continuation of’ the sidepod height design. KTM closes the gap between the sidepod and the bottom bulge so that the sidepod looks smooth as it blends with the bulge area at the bottom.

This bulging area when the motorbike tilts down will produce a fairly narrow gap between the fairing surface and the asphalt surface. The convex part of the lower fairing is even more bloated when compared to the first aero solution of 2024.

This means that in general and in plain view, with the second solution being tested, the KTM RC16 is alleged to be able to produce a downforce effect when tilted due to ground effect work, but with a slope that is not as extreme as the first solution in 2024.

The gap is narrow enough to force a venturi effect which will then speed up the air flow there. The fast flow of air will naturally make the air pressure in the gap low.

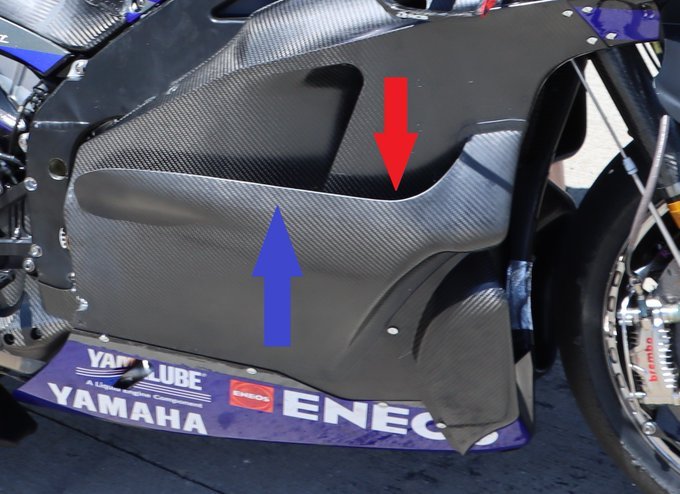

The presence of a sidepod solution with airway ‘chamfer’ details will ensure that the air flow from the side-pod is ‘trapped’ to be channeled to the ‘right way’ and does not mix with the air that flows between the narrow gaps between the fairing surface and the asphalt surface. The air gutter will ensure that the air flowing there remains at a higher pressure.

And because there are two pressure differences, this is enough material for the recipe to provide downforce when the motorbike is in a tilted position. This side fairing design with air tunnel was also tested by the Yamaha Factory, which now has aerodynamic engineers from the Dallara (Italy) manufacturer who are already skilled at making open wheeler racing cars such as Formula 2 and Indy Car as well as the Endurance prototype class.

The effect on the motorbike is that the motorbike seems to be sucked in by the asphalt of the circuit at high speed (because the fluid pressure of the air flow is directly proportional to the speed of the object’s movement) thus increasing stability and also high cornering speed and then creating a feeling of confidence in the racer going through corner after corner.